Ball Tube Diamond Cutting Machine

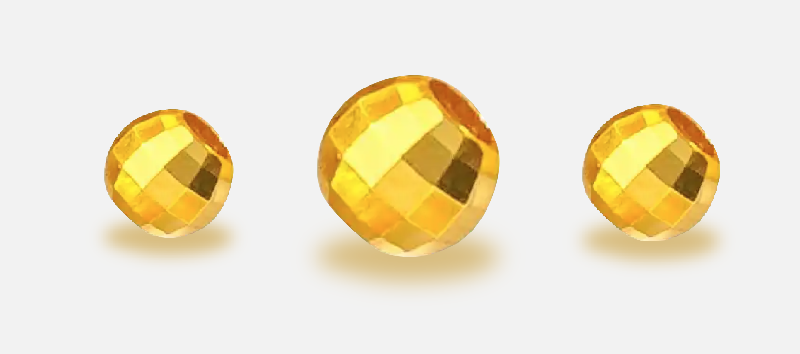

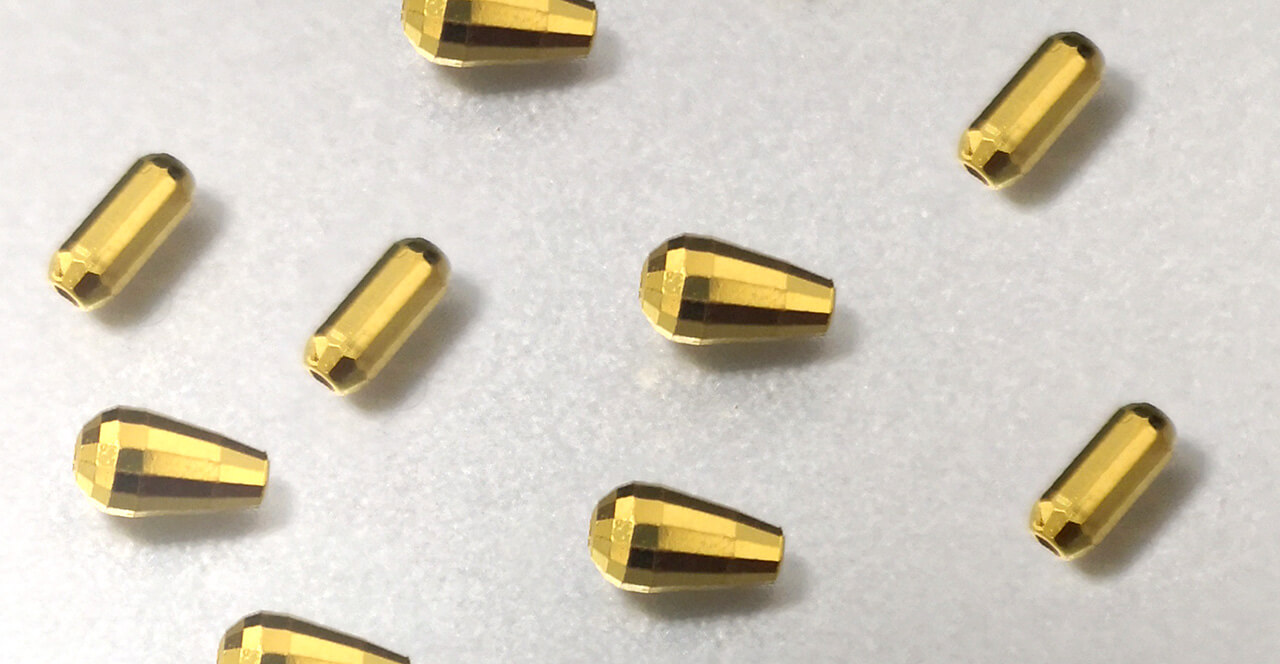

The Sible Automatic Ball & Tube Diamond Cutting Machine is a high-performance solution for modern jewelry manufacturing. Designed to process both ball and tube beads, this CNC-controlled machine delivers precise cutting, uniform size, and decorative surface patterns, such as disco, laser, and twill effects. It is compatible with gold, silver, copper, and K-gold, allowing jewelry manufacturers to produce high-quality beads with minimal manual intervention. The automatic feeding and cutting system ensures high efficiency, consistent results, and scalable production, making it ideal for workshops and factories seeking to improve productivity while maintaining top-quality decorative effects.

Bullet Points

Precision Cutting: CNC-controlled cutting for both ball and tube beads (1.6–8.0 mm).

Decorative Patterns: Supports disco, laser, twill, and customizable surface effects.

Wide Material Compatibility: Works with gold, silver, copper, and K-gold.

High Efficiency: Automatic feeding and cutting reduce manual labor.

Consistent Quality: Ensures uniform bead size, shape, and surface finish.

Versatile Applications: Suitable for jewelry workshops, factories, and decorative bead production.

Easy Operation: User-friendly interface with stable and reliable performance.

FAQ

Q1: What is the diameter range for beads this machine can handle?

A1: It supports beads with diameters from 1.6 mm to 8.0 mm.

Q2: Which materials are compatible?

A2: Gold, silver, copper, and K-gold are all suitable.

Q3: Can it create decorative patterns on beads?

A3: Yes, it can produce disco, laser, twill, and other customizable effects.

Q4: How much manual labor is required?

A4: Minimal. Automatic feeding and CNC-controlled cutting significantly reduce manual work.

Q5: Is it suitable for mass production?

A5: Yes, it is designed for high-efficiency, scalable production while maintaining consistent quality.