Diamond Wire Cutting Machine for Precision Jewelry Manufacturing

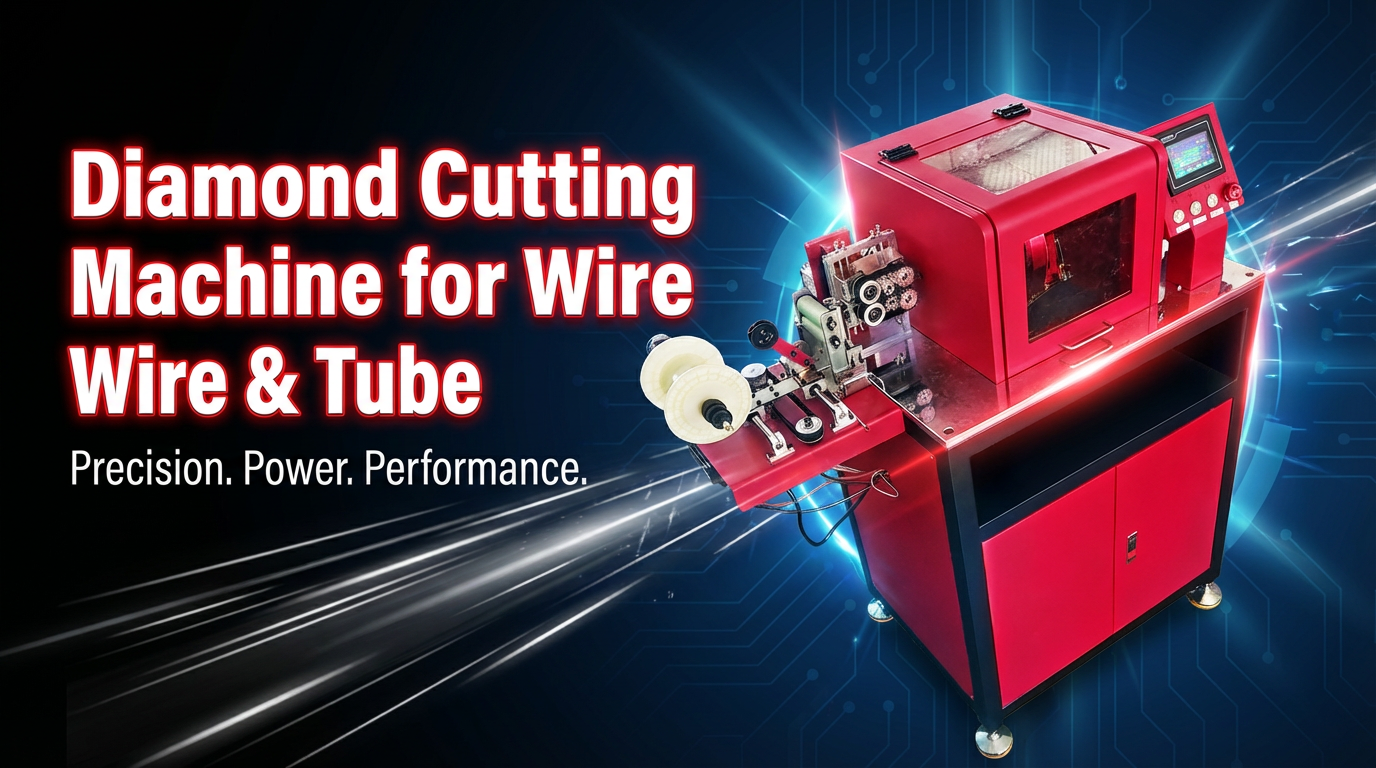

In modern jewelry manufacturing, precision and efficiency are critical for maintaining consistent quality and reducing production costs. The Diamond Wire Cutting Machine by Sible Jewelry is designed to meet these demands, offering accurate and reliable cutting solutions for round wires and tubes made from precious and non-precious metals.

As jewelry designs become more complex, traditional manual cutting methods can no longer meet the requirements of high-end production. Automated diamond cutting technology allows manufacturers to improve output while ensuring superior surface quality and dimensional accuracy.

High-Precision Cutting for Wires and Tubes

The Sible Diamond Wire Cutting Machine is suitable for cutting round wires and hollow or solid tubes with diameters ranging from 0.35 mm to 4.5 mm. Equipped with diamond cutting tools and a stable mechanical structure, the machine delivers clean, burr-free cuts that are difficult to achieve manually.

Thanks to its precise control system, this machine ensures consistent cutting depth and smooth finishes, making it ideal for jewelry components that require tight tolerances. Whether you are processing gold, silver, copper, or other jewelry metals, the cutting quality remains uniform across batches.

Automated Operation for Higher Efficiency

Automation plays a vital role in modern jewelry workshops. The diamond wire cutting machine features an automatic feeding and cutting system, significantly reducing the need for manual labor. This not only lowers the risk of human error but also improves overall production efficiency.

Compared with manual cutting, automated diamond cutting allows manufacturers to:

Increase daily output

Maintain consistent product quality

Reduce material waste

Lower long-term labor costs

For businesses aiming to scale production, this machine provides a reliable and cost-effective solution.

Ideal for Jewelry Manufacturing Applications

The diamond wire cutting machine is widely used in:

Jewelry wire cutting

Tube preparation for bead production

Semi-finished jewelry components

Precision metal cutting for decorative elements

It works seamlessly alongside other automated equipment. For example, after cutting wires or tubes, manufacturers can continue processing with the Ball Tube Diamond Cutting Machine to create decorative patterns on beads, or integrate with the Automatic Ball Diamond Cutting Machine for advanced bead finishing.

These combinations help form a complete automated jewelry production line.

Durable Design and Easy Maintenance

Built with industrial-grade components, the Sible diamond wire cutting machine is designed for long-term operation in jewelry factories. Its robust structure ensures stable performance even during continuous production. In addition, the machine is easy to operate and maintain, reducing downtime and training costs.

Clear control interfaces and straightforward adjustments allow operators to quickly switch between different wire or tube sizes, improving production flexibility.

Why Choose Sible Jewelry Cutting Machines?

Sible Jewelry specializes in precision jewelry cutting equipment, offering reliable machines tailored to real manufacturing needs. Each machine is developed with a focus on accuracy, efficiency, and durability.

By choosing Sible, manufacturers gain access to:

Professional jewelry cutting solutions

Stable and repeatable cutting performance

Technical support and customization options

A complete range of jewelry diamond cutting machines

To explore more automated solutions, visit the Jewelry Diamond Cutting Machine collection and discover equipment designed to optimize every stage of jewelry production.

Conclusion

The Diamond Wire Cutting Machine is an essential tool for jewelry manufacturers seeking precision, efficiency, and consistent quality. With automated operation, wide material compatibility, and high cutting accuracy, it helps businesses improve productivity while maintaining excellent craftsmanship.

For manufacturers looking to upgrade their cutting process and build a more efficient production line, the diamond wire cutting machine from Sible Jewelry is a dependable and future-ready choice.