How Ball Tube Diamond Cutting Machines Improve Jewelry Production Efficiency

In modern jewelry manufacturing, efficiency and precision play a critical role in meeting growing market demand. Traditional manual cutting methods are no longer sufficient for producing consistent, high-quality decorative tube beads. This is where ball tube diamond cutting machines offer a powerful solution.

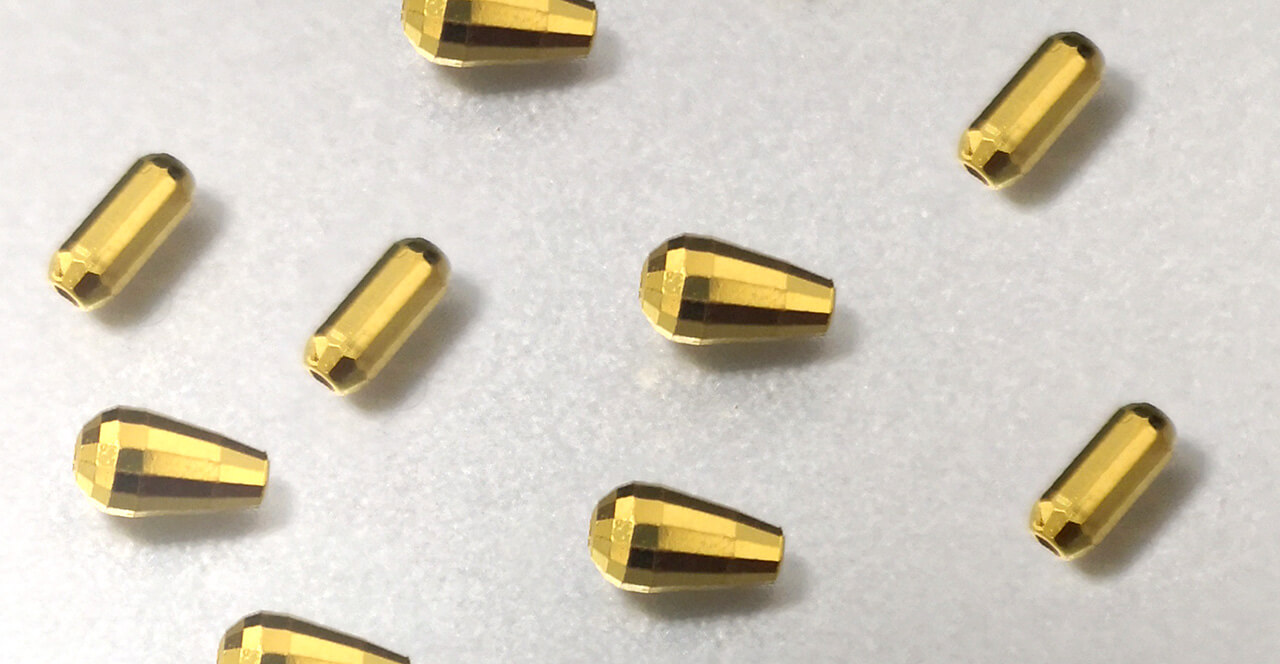

A ball tube diamond cutting machine is designed to automatically process hollow tube beads with high accuracy, creating decorative surface patterns such as disco, laser, and twill effects. Compared with manual processing, automated diamond cutting ensures uniform cutting depth, smooth finishes, and repeatable results across large production volumes.

One of the biggest advantages of using an automatic ball tube diamond cutting machine is the significant reduction in labor costs. CNC-controlled feeding and cutting systems minimize human error while improving production speed. Jewelry manufacturers can achieve higher output with fewer operators, making the production process more stable and cost-effective.

In addition, these machines are widely used for processing gold, silver, copper, and K-gold materials. Their versatility allows manufacturers to quickly switch designs and patterns, meeting diverse customer requirements without sacrificing precision.

For jewelry workshops and factories looking to upgrade their production lines, investing in a Ball Tube Diamond Cutting Machine provides long-term benefits in efficiency, quality consistency, and competitiveness.