Jewelry Production Automation Trends – Transforming Modern Manufacturing

Introduction

The jewelry industry is undergoing a significant transformation driven by automation technologies. As global demand for high-quality jewelry continues to grow, manufacturers are increasingly adopting automated production solutions to improve efficiency, reduce labor costs, and maintain consistent product quality. In this article, we explore the latest trends in jewelry production automation and how they are reshaping the future of the industry.

1. Rise of CNC and Robotic Systems in Jewelry Manufacturing

The integration of Computer Numerical Control (CNC) and robotic systems is one of the most impactful trends in jewelry automation. CNC machines provide unmatched precision for cutting, engraving, and shaping precious metals and gemstones. Robotic arms and automated feeders further streamline repetitive tasks, such as polishing and assembly.

Benefits:

Consistent and accurate processing

Reduced human error

Faster production cycles

These systems are widely used for diamond cutting, bead shaping, chain making, and more, enabling production at scale without sacrificing quality.

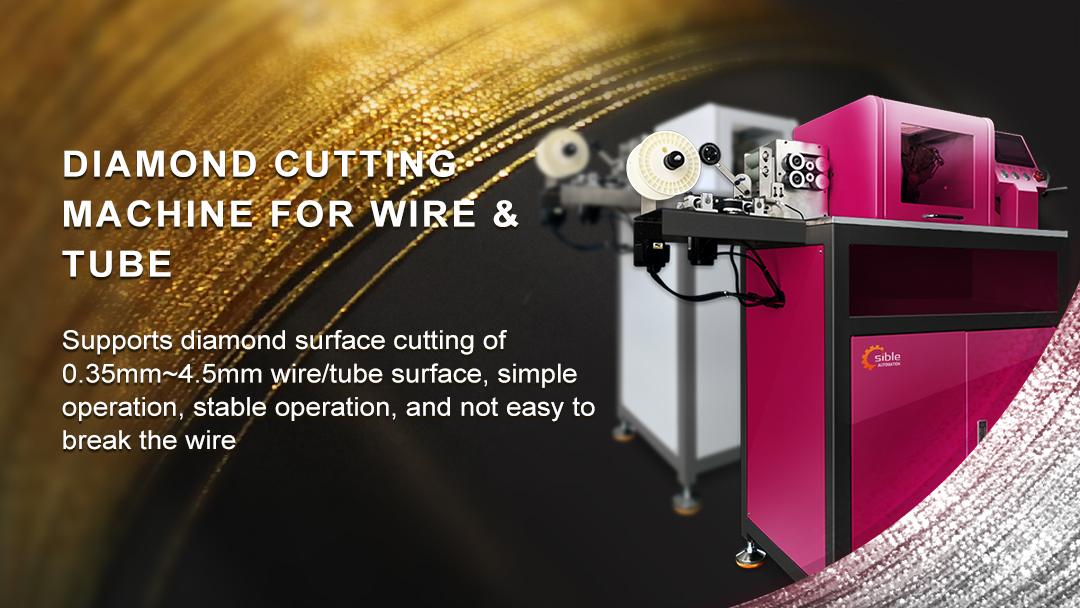

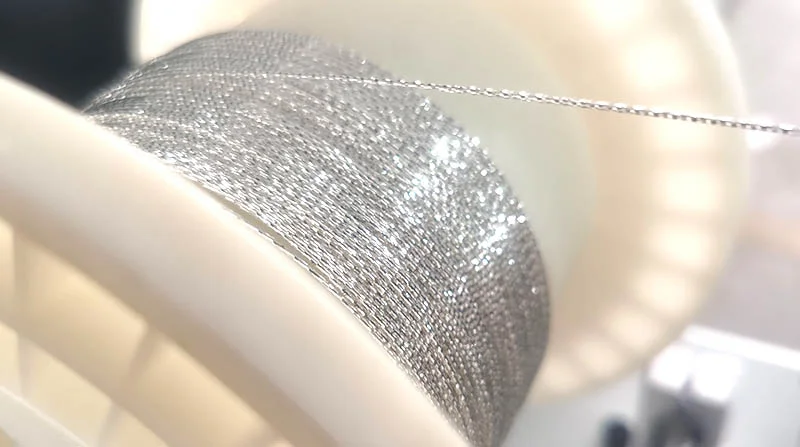

2. Automated Diamond Cutting and Bead Processing

Automated diamond cutting machines are quickly becoming indispensable tools for jewelry manufacturers. These systems use advanced numerical control and precision tooling to cut diamond patterns and surface finishes on beads, tubes, and other components.

Key advantages include:

High precision with minimal material waste

Decorative surface effects (e.g., laser, twill, disco patterns)

Increased production speed

Thanks to automation, tasks that once required skilled manual labor are now performed with higher consistency and speed.

3. Smart Quality Control with Vision Systems

Another significant trend is the adoption of machine vision and inspection systems. Automated quality control tools use cameras and software to evaluate jewelry components for defects, ensuring each piece meets exacting standards.

Machine vision benefits:

Real-time defect detection

Elimination of manual inspection errors

Integration with production lines for continuous monitoring

This trend not only improves product quality but also reduces returns and customer complaints.

4. Data-Driven Production and Industry 4.0

The concept of Industry 4.0 is reshaping jewelry factories worldwide. Production lines equipped with smart sensors and connectivity solutions collect real-time data, enabling predictive maintenance and performance optimization.

Key focus areas:

Predictive maintenance to minimize machine downtime

Data analytics for efficient workflow management

Integration of ERP (Enterprise Resource Planning) systems

Data-driven processes allow manufacturers to make informed decisions and adapt to market demand quickly and efficiently.

5. Sustainability and Efficiency in Jewelry Manufacturing

Sustainability is no longer an afterthought—today’s manufacturers seek automation solutions that reduce waste and optimize resource use. Automated cutting and shaping systems generate less scrap metal compared to traditional manual processes, and smart tools help reduce energy consumption.

Automation contributes to:

Reduced material waste

Lower operational costs

Environmentally friendly production

These improvements support both economic and ecological goals, aligning with modern consumer expectations.

Conclusion

As jewelry production automation continues to evolve, manufacturers who embrace advanced technologies will enjoy increased efficiency, consistent quality, and improved competitiveness in the global market. From precision CNC cutting machines to smart quality control systems and data-driven production lines, automation is no longer just a trend—it’s the future of jewelry manufacturing.